Marine aluminum sheets are generally made of 5083 aluminum sheets, 5086 aluminum sheets, and 5454 aluminum alloy sheets, especially for ship decks and hulls, mainly some wide sheets, so the production requirements of marine aluminum sheets are more stringent than other products.

Marine aluminium grades introduction

5083 aluminum alloy: all-round profile with high strength and corrosion resistance

5083 aluminum alloy is an Al-Mg series alloy, which is widely used in shipbuilding for its excellent corrosion resistance, weldability and high strength. It is often used in decks, bottom outer sheets, engine pedestals and other parts that bear heavy loads. At the same time, due to its excellent seawater corrosion resistance, it is also used in fuel tanks, fuel systems, etc.

5086 aluminum alloy: the best choice for lightweight and durability

5086 aluminum alloy is known for its lighter density and good corrosion resistance, and is an ideal material for lightweight ship design. It is widely used in the fields of hull, deck and offshore platform, which not only reduces the weight of the hull, but also improves fuel efficiency and load-bearing capacity, and is particularly suitable for long-term marine environment applications.

5454 aluminum alloy: Expert in anti-seawater corrosion

5454 aluminum alloy has excellent seawater corrosion resistance and good strength, and is widely used in hulls, shipboards, fuel tanks and other parts. At the same time, it also performs well in the manufacture of pressure vessels in the chemical, oil and gas fields, and can meet the use requirements in harsh environments.

Advantages of aluminum alloy hull

Due to its unique properties, aluminum alloy has obvious advantages in hull manufacturing compared with traditional steel and wood:

1. Lightweight: The density of aluminum alloy is only one-third of that of steel. The hull made of aluminum alloy can greatly reduce weight, thereby improving ship speed and fuel economy.

2. Corrosion resistance: A dense oxide film will form on the surface of aluminum alloy, which has excellent seawater corrosion resistance and is particularly suitable for long-term use in marine environments.

3. High strength and toughness: While meeting the lightweight requirements, aluminum alloy has strength and toughness sufficient to withstand impact and external forces during navigation.

4. Easy processing and welding: Aluminum alloy has good formability and weldability, and can adapt to complex hull design requirements.

5. Environmental protection and recyclability: Aluminum alloy materials can be 100% recycled, which is in line with the trend of green manufacturing and sustainable development.

Application scenarios

High-speed boats and patrol boats:

5083 aluminum alloy is often used in the main structure of high-speed boats and patrol boats due to its high strength and fatigue resistance. This alloy can effectively cope with the strong impact generated during high-speed navigation, and at the same time has long-term corrosion resistance to ensure the durability of the hull.

Medium-sized transport ships and fishing boats:

For medium-sized transport ships and fishing boats, 5086 aluminum alloy is the first choice due to its better welding performance and low temperature resistance. This material can maintain good toughness in extremely cold waters and is particularly suitable for ship design in the Arctic and cold waters.

Chemical tankers and oil tankers:

5454 aluminum alloy is widely used in tanks and shells of chemical tankers and oil tankers due to its excellent high temperature resistance and corrosion resistance. It performs stably in harsh environments containing chlorides, reducing corrosion and maintenance costs.

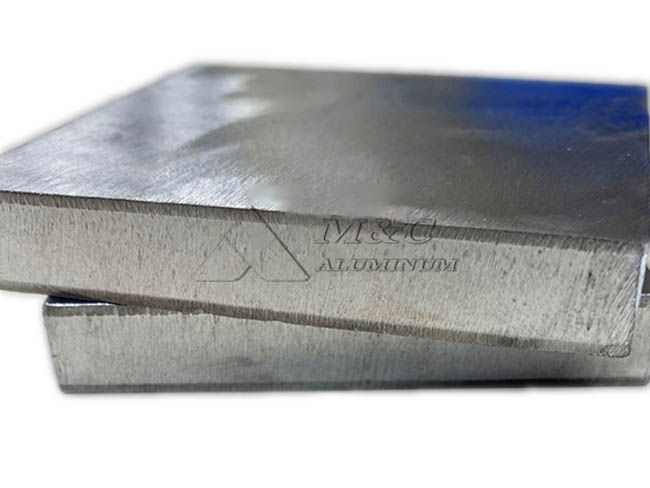

Marine aluminum sheet specifications

| Alloy | 5083, 5086, 5454, etc |

| Temper | H32, H116, H321, etc |

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 1000-16000mm |

| Welding technology | MIG, TIG |

| Surface treatment | anodizing |

| Classification society certification | CCS, DNV, NK, CCS, ABS, BV, LR, KR |

Chemical composition of marine aluminum alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.25 | 0.25 | 0.2 | 0.05 | 0.15 | remainder |

Performance comparison of 5083, 5086 and 5454 aluminum alloys

| Alloy model | Main features | Application scenarios |

| 5083 | - One of the strongest Al-Mg alloys - Excellent seawater corrosion resistance - Good weldability and processing properties | - High-speed hulls, deep-sea work vessels, marine equipment |

| 5083 | - Slightly lower strength than 5083 - Excellent corrosion resistance - Excellent low temperature resistance | - Small and medium-sized ship hulls, coastal patrol boats, cargo ship outer plates |

| 5454 | - Outstanding corrosion resistance, especially in chloride environments - Good fatigue resistance - Higher temperature resistance | - Tankers, chemical tankers, and some marine container manufacturing |

MC Aluminum's marine aluminum sheets are mainly 5 series. Its 5083 ship sheets, 5086 aluminum sheets, 5052 aluminum sheets, 5383 aluminum sheets and other products have passed the certification of China Classification Society and have become the main supplier of many large overseas shipbuilding companies. The product models are complete, exported overseas, with preferential prices, free samples are provided, and customers can visit the factory.