Aluminum alloy profiles are becoming the core material in the field of boat manufacturing due to their lightweight, high strength, corrosion resistance and good processability. As the modern shipbuilding industry develops towards high efficiency, energy saving, environmental protection and sustainability, aluminum alloy profiles are increasingly used in hull structures, interior cabin decorations and auxiliary equipment, which not only improves the performance of the ship, but also significantly reduces maintenance costs.

Aluminum alloys commonly used in the field of boats mainly include the following categories

5XXX series aluminum alloys (such as 5052, 5083, 5456): excellent corrosion resistance, suitable for manufacturing ship hulls and decks.

6XXX series aluminum alloys (such as 6061, 6082): have high strength and are suitable for hull frames and structural components.

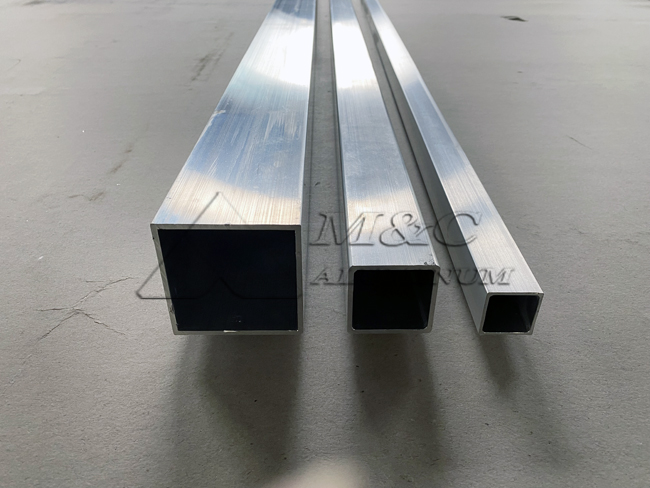

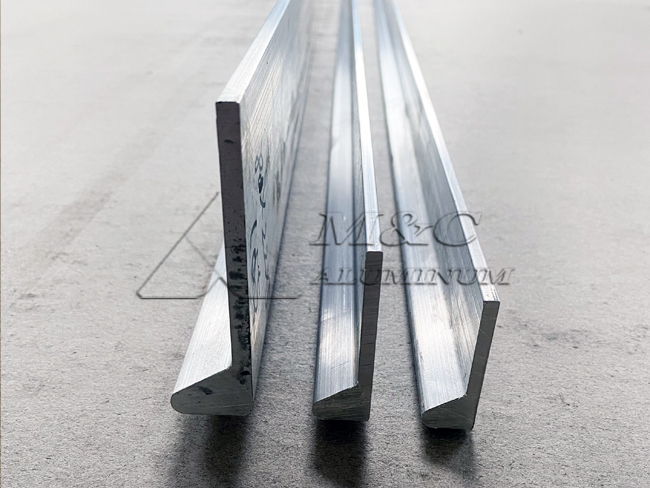

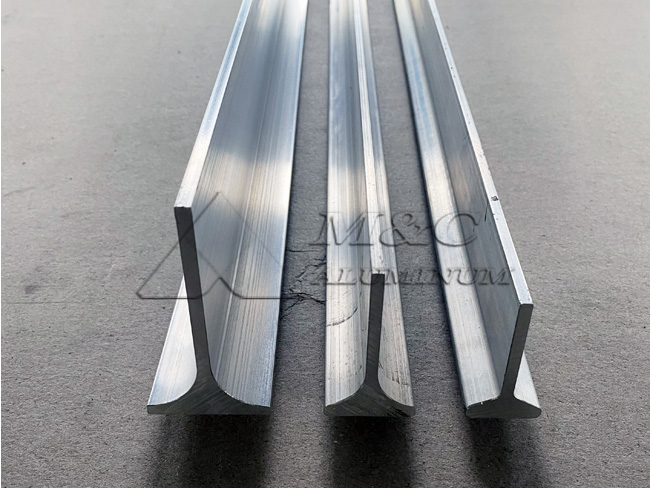

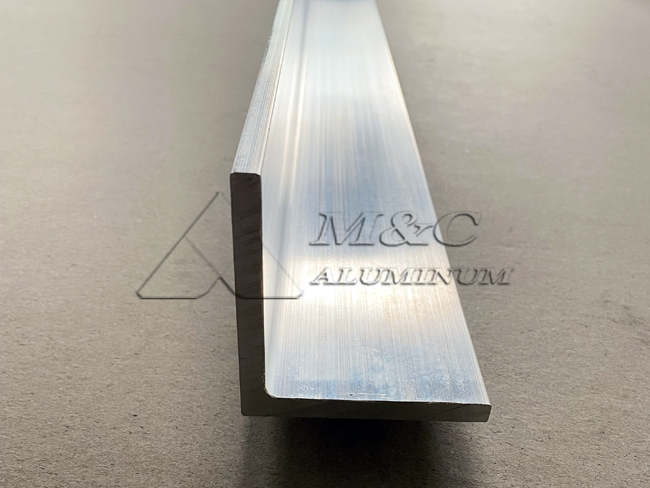

Extruded aluminum profile applications

Hull structure: Aluminum alloys are commonly used in the manufacture of hulls for high-speed boats, yachts and fishing boats. The main components include hull plates, frames, decks, etc.

Cabin and decoration: Aluminum alloy profiles are widely used in interior cabin frames, doors, windows, handrails and decorative panels.

Provides lightweight design while maintaining beauty and durability.

Ship equipment and facilities: used to manufacture masts, railings, ladders, antenna brackets and other components.

Propulsion and auxiliary systems: Aluminum alloy profiles are used for propeller casings, cabin frames, etc.

Features of marine grade aluminum profiles

1. Lightweight: The density of aluminum alloy is 1/3 of steel, which reduces the weight of the boat and increases the load capacity and speed.

2. High strength and workability: Aluminum alloy can achieve high strength after heat treatment or cold processing, which meets the requirements of ship structure.

3. Corrosion resistance: It has good corrosion resistance in marine environment and has a longer service life after anodizing treatment.

4. Cost-effectiveness: Although the unit price of aluminum alloy is higher, the low maintenance cost and long service life make the cost-effectiveness better than traditional materials.

5. Recyclability: Aluminum alloy has a high recycling rate, which is helpful for environmental protection and sustainable use of resources.

MC Aluminum is a manufacturer specializing in the production of marine-grade aluminum alloys, including 5083 marine aluminum sheets, 5052 aluminum sheets, 6061 aluminum sheets, aluminum profiles, ribbed plates and other products, which are used in shipbuilding and offshore facilities. Provides CCS, BVLR, ABS, DNV-GL and other certificates. The product quality is stable and exported to many overseas countries. Factory direct sales can be customized according to customer needs, with favorable prices and guaranteed after-sales service.