Hot-rolled marine aluminum plate is a high-performance aluminum alloy plate designed for marine environment, mainly used in shipbuilding, marine engineering and other fields with high corrosion resistance requirements. This type of aluminum plate is produced by hot rolling process to ensure that it has good mechanical properties, excellent corrosion resistance and stable internal structure.

What is hot-rolled aluminum plate?

Hot rolling usually refers to the rolling process carried out at a temperature higher than the crystallization temperature of the metal. Hot-rolled aluminum plate is made by heating aluminum plate ingots (400~500mm thick) at high temperature and then rolling them through a hot rolling mill. The hot rolling process can ensure that the aluminum plate has good surface quality while enhancing its ductility and mechanical properties.

5083 aluminum alloy is a high-strength anti-corrosion alloy based on aluminum-magnesium system, with good strength, corrosion resistance, machinability and weldability, as well as medium strength. In addition, after anodizing, its surface is beautiful and the arc welding performance is good. The H116 state indicates that it has undergone a specific hardening treatment and has excellent seawater corrosion resistance.

5083 H116 hot-rolled marine aluminum plate can be processed and customized according to customer needs, including cutting, bending, welding and other process flows. At the same time, anodizing and other services can also be provided to meet customers' diverse needs for material performance and appearance.

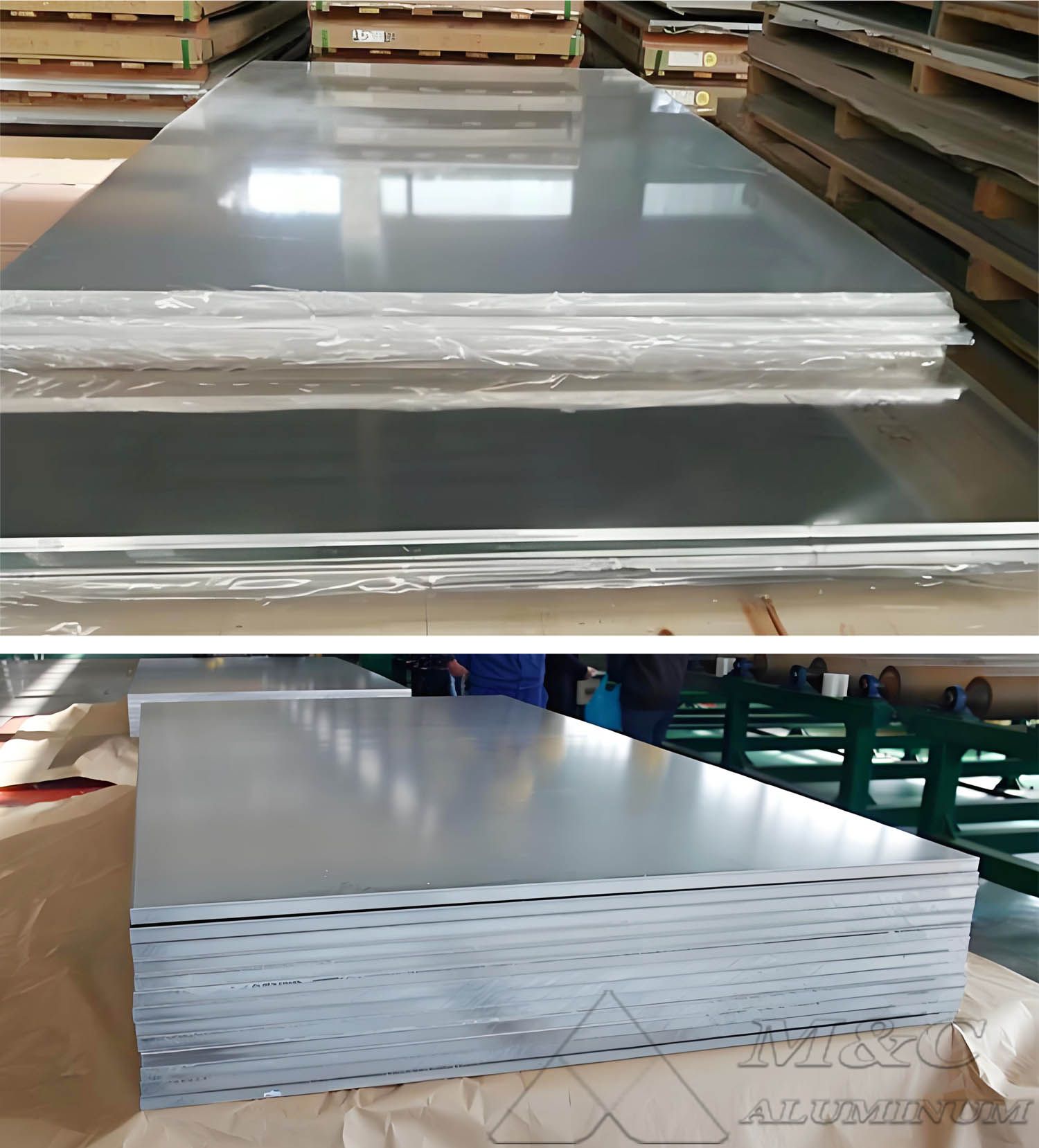

5083 marine aluminum plate specifications

| Temper | H116, H321, etc |

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | C |

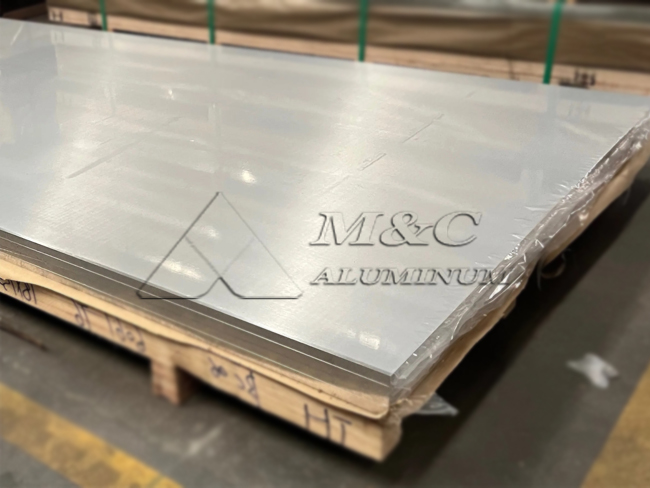

| Packaging | export standard wooden pallet |

| MOQ | 1-3 tons |

Mechanical properties

| Tensile strength σb (MPa) | Conditional yield strength σ0.2 (MPa) | Elongation δ10 (%) | Elongation δ5 (%) |

| ≥ 305 | ≥ 215 | ≥ 20 | ≥ 12 |

Chemical composition of 5083 aluminum alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

5083 H116 marine aluminum plate advantages

1. High strength: The hot rolling process improves the strength of the aluminum plate and can resist impact and corrosion in the marine environment.

2. Good ductility: Hot-rolled aluminum plates are easy to process and suitable for manufacturing shapes and structures.

3. Excellent corrosion resistance: After special treatment, the aluminum plate can be stable for a long time in the marine environment.

4. Lightweight: Aluminum has a low density, which reduces the weight of the hull and improves fuel economy.

5. Excellent welding performance: Easy to weld, and stable performance after welding.

5083 H116 marine aluminum plate application areas

1. Maritime use: It is the preferred material for the shipbuilding industry and is used to manufacture sheet metal parts for ships.

2. Transportation: Used in the manufacture of automobiles, aircraft welding parts, subway light rail and other transportation vehicles.

3. Pressure vessels: Suitable for containers that require strict fire protection, such as liquid tankers, refrigerated trucks, refrigerated containers, etc.

4. Other fields: It is also used in refrigeration equipment, TV towers, drilling equipment, transportation equipment, missile parts, armor, etc.

MC Aluminum is a professional marine aluminum plate manufacturer, producing 5083 marine aluminum plates, 5052 aluminum plates, 6063 aluminum plates, 6061 aluminum alloys, aluminum profiles, ribbed plates and other products for shipbuilding and offshore facilities. The products have multiple certificates such as CCS, BVLR, ABS, DNV-GL, etc. They are exported to many countries overseas and are highly trusted. The company has large output, fast delivery and favorable prices.